Master Planning Unplugged, Volume 3: Reducing the Noise

You are here: >Master Planning Unplugged, Volume 3: Reducing the Noise

Hello and welcome to our continuing series of blogs devoted to the world of Master Planning in AX. The first 2 volumes focused on the setup options for your Master Plans, as well as defining coverage.

However, you’re probably still wondering why I decided to call this series “Master Planning Unplugged.” Since I love using analogies, this tile actually came from one of my favorite ways to listen to music: Unplugged.

When a musician can strip down their art to the most basic of instruments and vocals, it can often bring out the best in their sound. And that’s what I want to talk about today. How do you strip down Master Planning to reduce the “noise” and get the best results from Dynamics AX?

In this third installment, we will focus on three main areas in relation to minimizing the non-value added data in your planned orders and Net Requirement forms:

-

Time fences and their effects on the Supply chain

-

Positive and negative days

-

Understanding Actions and Futures

In the last blog post on setting up coverage, we briefly discussed Time fences. Time fences are always stated in a value of days. There are Time fence settings in Master Plans, Forecast Plans, Coverage groups, and Demand forecasting. Knowing which Time fences control certain behaviors is extremely important.

Let’s start with the Time fences within the Master Plans, as there is quite a few. The first one you will come across is in the General tab and is called the Finite Capacity Time Fence:

This field is only available if the “Finite capacity” box above it is set to “Yes.” This is used with production scheduling to specify the number of days during which planned production orders are scheduled with finite capacity. Finite capacity means that you are taking into consideration time that has already been reserved against the resource to determine when something can be manufactured.

If the capacity can change based on the requirement changes, typically this would not be used. Also, to use this field correctly, you must ensure your resources and resource groups are set to use Finite capacity as well.

There is a corresponding setting in Coverage groups that will override the setting on the Master plan for items that belong to that group. Also, as you see above, there is a similar setting for resources setup to be bottlenecks. Next, there is the Time fences tab itself:

In my environment, I have all of these turned off and that’s because most companies will not enable these unless all items in the company have the same lead times and coverage needs. If I did enable these fences, it would override any of the same

Time fence settings in the coverage groups, which are there to specify your days for groups of similar items, which are more commonly used. However, let’s define what each of these are now. The “Coverage” is a Time fence that controls how far from the current date Master Planning will consider requirements for. Any transactions that have requirement dates beyond that date, are not considered in Master Planning.

This value will be at a minimum equal to the lead time of the items, if not greater than the lead time. “Freeze” is the number of days planned orders cannot be created and previously created planned orders will not be deleted or changed during MRP regeneration.

All demand that is not covered in this number of days are covered by supply (PO or Production order) that is created at the end of the period, together with an action message that suggests advancing the date of the planned order. During the period, if an earlier requirement calculation created a planned purchase order, that order remains in the period and is not moved.

A real life example of this would be: The Freeze Time fence is 5 days. A sales order has a ship date in 2 days, and there is no inventory that can cover the requirement. The requirement calculation proposes that the planned purchase order be delivered in 5 days. In my experience, this setting is used much less frequently than other time fences.

“Firming” time fences enable some automation into the Master plan. Firming is the number of days from the current date that planned orders should be automatically firmed. So if the value was set to 2 days, and the requirement date was within that timeframe, the planned order would be automatically firmed without expecting someone to review it.

This can be useful in a very stable and consistent environment where it’s not required to review every planned order. The “Explosion” Time fence is only relevant if you are using Production in AX, where the planned production orders for items on Bills of Materials are “exploded” into requirements to supply those components.

The “Capacity” time Fence is also related to production to determine the number of days planned production orders are capacity schedule. Master planning uses the item’s active production route and plans scheduling based on the requirement date. “Forecast plan” time fences are how far from current date the forecast is planned for in the Master plan.

We won’t discuss continuity plans in detail but they are similar to forecasts and built almost like when a customer has a subscription where you ship to them predefined items on a recurring basis. The “Action messages” and “Calculated delays” Time fences related to suggestions on how to change planned orders, whether that be adding or subtracting a quantity, or moving dates to be earlier or later based on changes in demand. Let’s take a look at those more closely.

Calculated Delays, previously called “Futures messages,” are suggestions or warnings to notify the user that either a Sales order or production order is not estimated to be completed by the requirement date. It instead suggests the date that the order should be completed by based on the current schedule of on-hand and supply.

It also can be used as the requirement date if you accept that the “Calculated delay” should be the real source of the date. Some companies do not like to set those 4 checkboxes above to “Yes” because if the Requirement date is the “Calculated delay” and the item is manufactured, that will also suggest to push out the requirement of the components needed to make the item, and you may have still wanted to bring those items in at the original date. So be sure you arrange these settings based on when you want to see the demand.

We will cover the different types of “Action messages” when we get to the Coverage groups later in this blog. Lastly, as part of the Master Plans, we have Safety margins.

Safety margins are buffer days that allow you to add or subtract days from the requirement date to ensure product is arriving and shipping on time. Receipt margins are days added to supply. So if a Purchase orders had an expected delivery date of 6/20 and the Receipt margin was 2 days, the requirement date would be 6/22. This is useful when you have long processing time for the warehouse to receive and put away a product, so the receipt margin allows us to plan for that processing time.

Issue margins are very similar but apply to days reduced from the issue requirement date. For example, a sales order is requested to ship on 6/30 and the Issue margin is 1 day, the requirement date to have that item on-hand and sent to the warehouse will be 6/29 to ensure the processing time in the warehouse or administrative tasks is covered. The reorder margin is a basic buffer lead time that is added to all planned orders during Master scheduling.

Now that we have looked at all of the time fences in Master plans, let’s go over the coverage groups. We mentioned earlier that the majority of companies will disable the time fences on the Master plan so that they can be more granularly applied at the Coverage group level. Those values will be applied in the General and Other tabs of the Coverage Group.

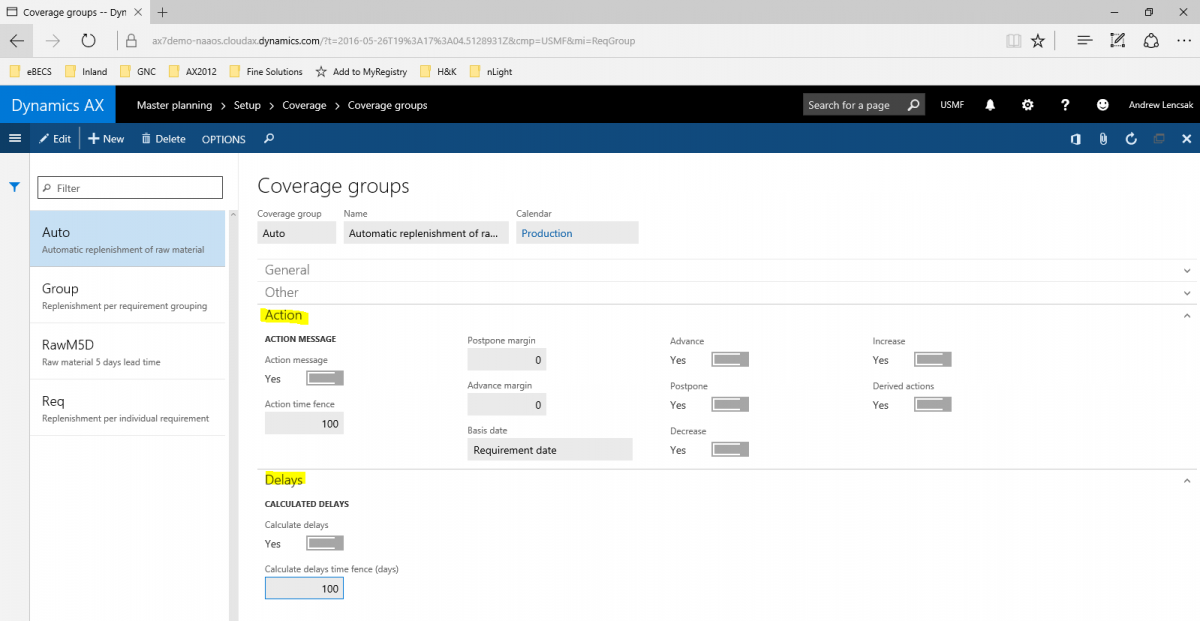

Beyond that, the Actions and Delays tab can also be specified. This is one of the key areas in reducing the “noise” of planning. We already discussed how Actions and Delays are suggestions to alter your planned and existing orders to satisfy any changes in demand. If set incorrectly, you can end up with many more of these notices than is reasonable acceptable to review on a day-to-day basis.

The Time fences in these tabs specify the number of days from the current date that messages will be applied. In the case above, our Action time fence is 100 days. If the Coverage time fence was 180 days, Action messages would only apply to requirements within the next 100 days.

You also have the ability to specify which types of Actions you want to get messages for: Advance and Postpone date notices, Increase and Decrease of quantity notices, and Derived actions which explode any Actions messages of a Production item to the lower level components.

There is one more major feature in the Coverage groups to consider and that is Positive and Negative days. To put it simply, Positive days are the number of days to use existing inventory before a new planned PO is generated.

So if a sales order delivery date is more days out than the Positive days, a planned PO is generated. If the order date is less than Positive days, then planning proposes to use existing inventory to fulfill the order.

The main reason for Positive days is to limit the number of planned orders, and the recommendation is that this setting is equal to the Coverage time fence. Negative days are the number of days to consider planned receipts for sales orders. An example explains this more clearly: if the sales order is due to ship today, and the Negative days is set to 2 days, supply with a receipt date of two days from now or sooner will be used to meet the demand, otherwise a planned PO will be generated. So to put it in plain English, Negative days allows late supply to fulfill the demand.

How to determine the amount of negative days to apply can be difficult and there are kind of two trains of though: make it as big as your Positive days or make it as low as possible. In addition to this, there is a setting in the Master plan that comes into play: Dynamic negative days.

When dynamic negative days is set, the lead time defined on the released product will always be the minimum negative date counted from the current date. If a demand is calculated in the future, then negative days will be equal to number of negative days set on the coverage group. When calculating with dynamic negative days, the negative days’ settings should be low, not the lead time of the product or the same as Positive days. Using dynamic negative days will help decrease the amount of Actions and Delays and all issues that are within lead time will always see receipts within lead time.

I will not go into any detail on the Demand Forecasting time fences, as Demand forecasting deserves its own blog, but it’s important to know that those control the amount of history to take into consideration when forecasting and the amount of time into the future that the new forecast will be generated for. With that, it leads me to the last point I want to make about reducing the chatter in your plan.

We have discussed the hierarchy of settings and what overrides each other. There are Master and Forecast plan settings, as well as Coverage group settings which work great for mass applying all of the values to large groups of items,

However, in some cases, you have certain items that don’t really fit into the same mold as other items, or have specific values that need to be different. You can override a lot of what we have discussed at the product level by using the Item coverage form. As you can see below, there are many fields that can be overwritten so that the specific item you are using has its own values for Time fences and messages in the case they differ from the Coverage group the item is in.

This is great for companies because now you can control planning and basically any level of granularity that you need! And that wraps up this volume on Master Planning. As you can see, deciding how to configure your plans, coverage groups, and items is not an easy or quick task, but hopefully this post gives you the ability to analyze your needs and adjust as necessary. Make sure to look out for the next installment of Master Planning Unplugged!

- About Us

- Partners

- Careers

- Contact us

- eBECS and the Microsoft Core Data Platform

- Microsoft Dynamics NAV in Property Management

- Microsoft Dynamics Nav Manufacturing Solutions

- Microsoft Dynamics NAV Cloud pricing

- Drive your Azure Momentum with SQL Managed Instance

- Compare Microsoft Dynamics AX VS NAV

- Microsoft Azure Data Centre Migration Guide

- Microsoft Dynamics 365 Business Central or 365 for Finance & Operations?

- Introduction to Microsoft Dynamics 365 for Finance and Operations

- Microsoft Dynamics 365 Business Central or 365 for Finance & Operations? Thank You

- Microsoft Dynamics 365 Business Central or Dynamics 365 Finance

- Compare Microsoft ERP Solutions

- Compare Microsoft ERP Solutions, Dynamics NAV vs Dynamics 365 Business Central

- Microsoft Dynamics 365 Business Central Price

- Compare Microsoft ERP

Categories

- AI (3)

- Azure (2)

- Business Insights (1)

- Canvas Apps (1)

- Common Data Service (2)

- Crisis Communication (1)

- CRM (3)

- Customer Data Platform (1)

- Customer Insights (1)

- Data Analytics/BI (29)

- Data Management (1)

- Data Warehouse (1)

- Dynamics 365 (33)

- Dynamics 365 Finance (1)

- Dynamics 365 Sales Insights (1)

- Dynamics 365 Supply Chain Management (1)

- Dynamics AX (50)

- Dynamics CRM (22)

- Dynamics Field Service (10)

- Dynamics NAV (10)

- Dynamics Project Service Automation (PSA) (15)

- eBECS (4)

- eBECS Marketing (1)

- eBECS Policies (1)

- ERP (2)

- Internet of Things (IoT) (15)

- Master Planning AX (4)

- Microsoft 365 (1)

- Microsoft Lifecycle Services (4)

- Power Apps (4)

- Power Automate (3)

- Power BI (1)

- Power Platform (6)

- Power VIrtual Agent (1)

- PowerApps (2)

- Project Service Automation (2)

- Quality Management (1)

- Sales (1)

- Surface Hub (3)

- Top Tips (1)

News

Upcoming Events - Register Now

Join our list

eBECS will invite you to webinars, events and keep you up to date with relevant news. You can unsubscribe at any time.